Sorry, your browser is not supported. For a better experience, keep your browser up to date. Check here for latest versions

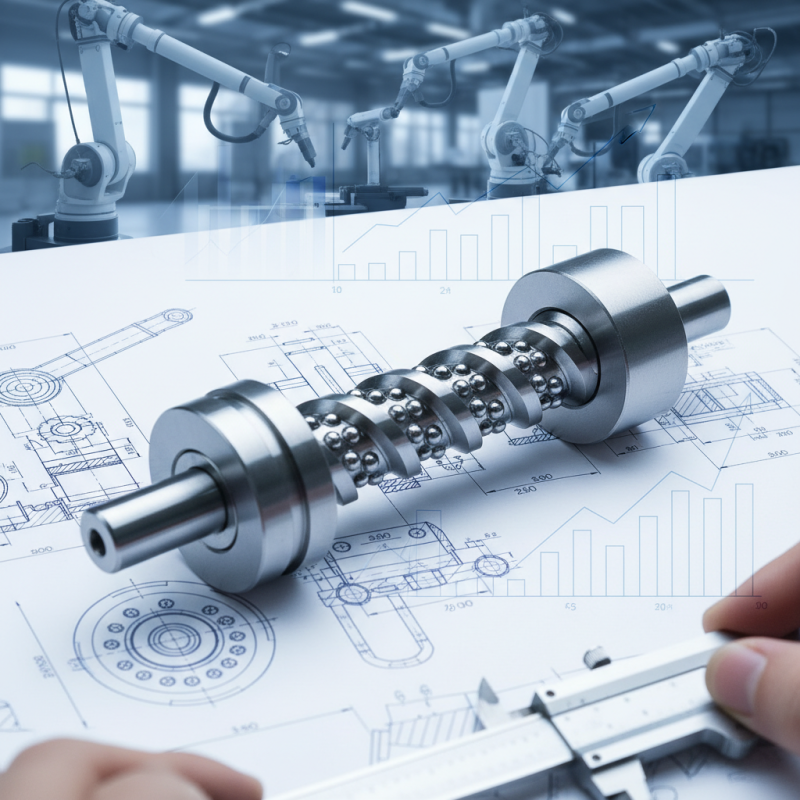

When selecting a ball screw for sale, project requirements must take center stage. The global market for ball screws is projected to grow significantly, reaching $3.2 billion by 2030. This data suggests that many industries recognize the value of precision in motion control. A quality ball screw enhances efficiency and accuracy, making it vital for automation systems, CNC machines, and robotics.

Choosing the right ball screw is not a simple task. Key factors like load capacity, lead accuracy, and material quality are essential considerations. The choice can affect project costs, performance, and reliability. Many projects fail due to overlooked specifications or miscalculations. It's a common pitfall; understanding your application fully can lead to a sound decision.

Working within budget constraints adds to the challenge. Some may opt for cheaper alternatives to the detriment of quality. This could lead to frequent maintenance or early failures. It's critical to balance cost with performance needs. A hasty decision could result in complications down the line. Reflection on past choices can guide future selections, ensuring the best fit for your project's success.

When selecting a ball screw for your project, several factors come into play. The first consideration should be load capacity. Understand the weight your application requires. A screw that is too weak can fail. Think about the maximum load you expect.

Another key factor is the screw diameter. A larger diameter can handle more load but may also take up more space. Match the screw size to your design. If you have limited space, a smaller screw may be necessary.

Tip: Always calculate the required torque for optimal performance. Torque affects how smoothly the screw can operate.

Additionally, consider the accuracy and repeatability of your application. Different ball screws offer various precision levels. If your project demands high accuracy, don’t overlook this aspect. Be aware that opting for low-cost alternatives might sacrifice precision.

Tip: Take time for research. Gather insights on various specifications before purchasing. Some detailed checks could save you from problems later on. Reflect on your specific needs carefully before making a decision. The right ball screw can make a significant difference in performance.

When selecting a ball screw, it's crucial to understand the various types available. Ball screws come in different configurations, each suited for specific applications. For instance, some ball screws are designed with a high load capacity, making them ideal for heavy machinery. Others focus on precision and are perfect for robotics or CNC machines.

Additionally, there are different materials used in manufacturing ball screws. Stainless steel offers corrosion resistance, while carbon steel provides strength. The choice between these materials can significantly impact performance and lifespan. There's also a range of lead options. A shorter lead provides higher resolution, while a longer lead offers faster movement.

However, choosing the right ball screw can be challenging. Many overlook the importance of matching the screw's specifications with the intended use. It's easy to make assumptions, but ignoring load limits or miscalculating travel distances can lead to failures. A thorough assessment of project demands is essential for ensuring optimal performance.

When selecting a ball screw for your project, it is crucial to evaluate load capacity and performance specifications. Load capacity is often determined by the screw's diameter, length, and the materials used. For instance, the load ratings of typical screws can range from 1,000 N to over 100,000 N. Analyzing these numbers helps ensure the screw can handle the intended load without failure.

Performance specifications such as speed, efficiency, and backlash are equally important. According to a recent industry report, screws with lower backlash offer higher precision but might compromise speed. It’s also noted that efficiency ratings can impact energy consumption. Some high-performance models boast efficiencies over 90%, while others fall below 70%.

Take time to scrutinize your project's requirements. What works for one application may not suit another. Miscalculating load capacity can lead to mechanical failure. Additionally, neglecting speed requirements might cause operational delays. Balancing these factors is key to achieving optimal results.

When selecting a ball screw for your project, assessing material quality is essential. High-quality materials ensure durability and performance. For instance, steel grades such as C45 and 1045 are commonly used. They can provide resistance against wear and fatigue. Research shows that components made from these steels can last up to 25% longer in high-stress environments.

Tips: Always check the material certifications. They can reveal details on tensile strength and other important properties.

Manufacturing standards also play a crucial role. Precision in the manufacturing process determines how well a ball screw functions. Tolerances should align with industry standards, often specified in ISO guidelines. A report by the American Society of Mechanical Engineers indicated that improperly manufactured screws can lead to a 30% increase in operational failure rates.

Tip: Request detailed manufacturing reports. This will help you evaluate the fabrication integrity.

Choosing the right ball screw can be challenging. Many overlook the significance of consistent quality during production. Regular audits of the supplier's processes can uncover potential issues. It's always beneficial to remain critical and inquisitive about those who provide your components.

Choosing the right ball screw for your project can be challenging. The balance between cost and quality is crucial. On one hand, high-quality ball screws can provide better performance and longevity. On the other, they come with a higher price tag. It's essential to evaluate your project's specific needs against potential costs.

Sometimes, cheaper options can seem appealing. They fit the budget easily, but could be a false economy. You may face issues like reduced precision. Problems can arise when the screw wears out quickly. It requires investing time and funds into replacements sooner than expected. The lower initial cost might disguise future expenses.

Quality ball screws may be costly upfront, but consider the long-term benefits. They often offer reliability and efficiency. Look for materials that withstand wear and tear well. Think about your project’s application. A delicate task may demand higher precision, making cost a secondary concern. Reflect on the total value, not just sticker price, to achieve the best outcome for your project.

This chart illustrates the cost comparison of ball screws across three different quality tiers, enabling you to assess the trade-off between cost and quality for your project.